Less batteries, more autonomy: Revolutionizing the electrification of heavy-duty vocational trucks

Effenco recently launched a new, 100% electric solution that is poised to radically transform the vocational trucking sector, one of the most polluting sectors of the transportation industry.

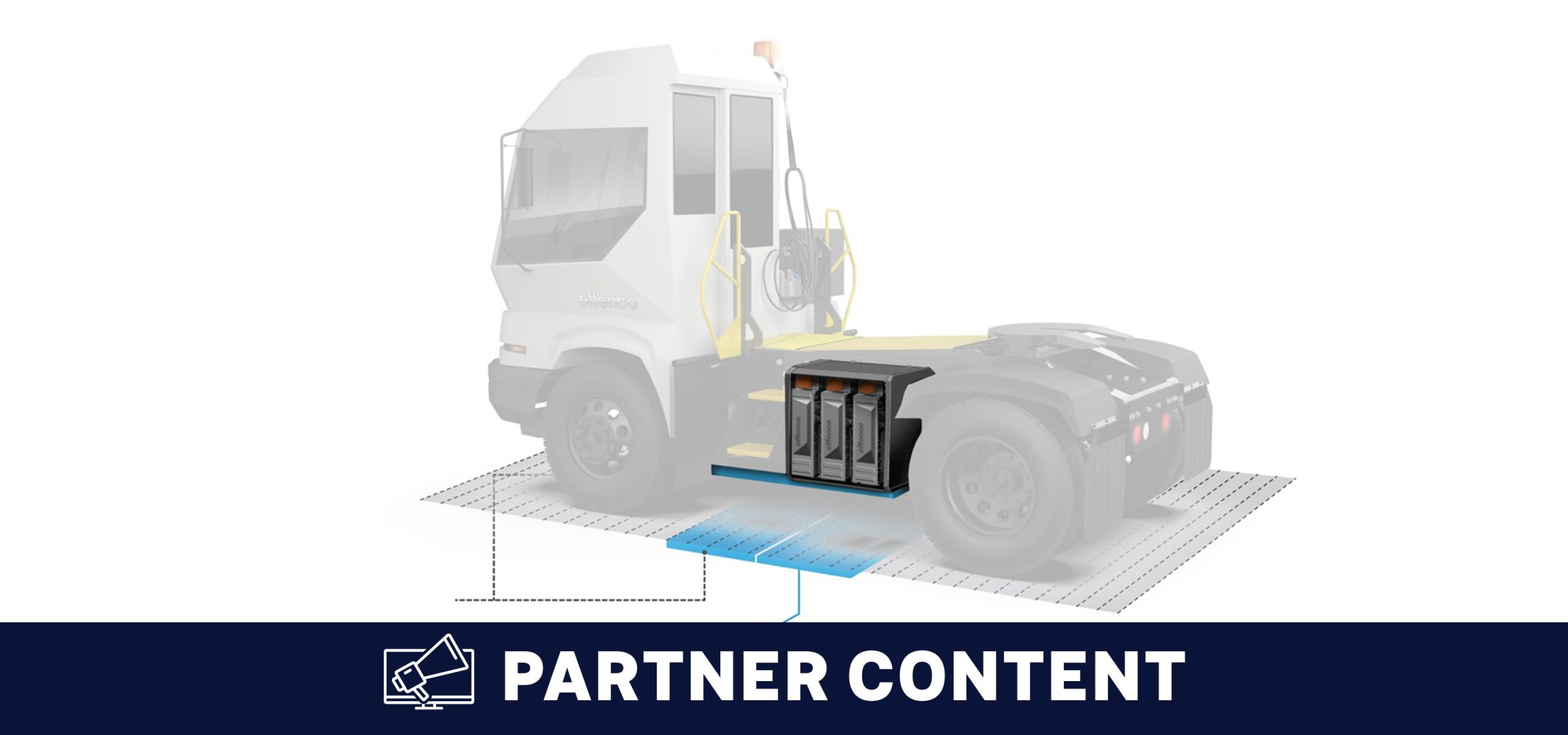

The company has developed a technological solution that makes it possible to offer a 100% electric heavy-duty vehicle at the same purchase price as diesel equivalents. The key is the pairing of supercapacitors, designed using Effenco’s patented technology, with wireless charging stations strategically positioned along the vehicle’s route using artificial intelligence (AI) algorithms. This unique solution allows a complete electrification of the vehicle with a fraction of the energy on board.

HURDLES TO ELECTRIFICATION – The biggest hurdles to mass adoption of electric vehicles remains cost of acquisition and deploying a recharging infrastructure. By offering a 100% electric heavy-duty vehicle at the same purchase price as a diesel equivalent, the main barrier to electrification is removed.

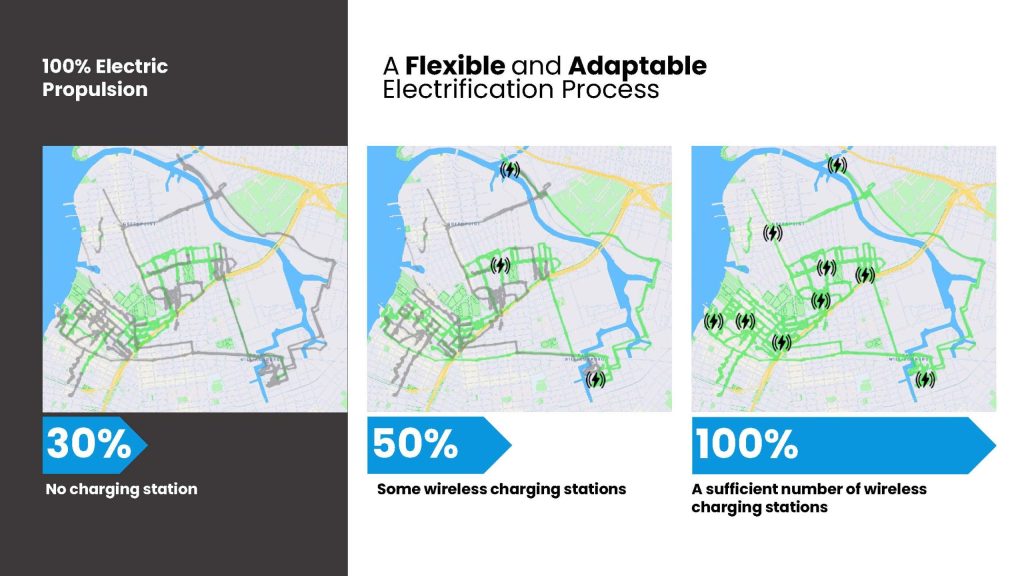

Should fleet operators opt for a gradual implementation of their charging infrastructure, the company offers range extender options that allow for a transition to full electrification, with an initial 30% reduction in greenhouse gas emissions (GGE) associated with improved vehicle fuel efficiency. Full electrification can be achieved gradually as the wireless charging infrastructure is deployed along the vehicle’s route, thus eliminating the second barrier to electrification.

ELECTRIFY DIFFERENT – Effenco, whose name is based on the term “energy efficiency,” has always had a unique way of approaching obstacles. The company first looked at how to reduce the amount of energy a heavy-duty vocational truck requires to perform its tasks. After collecting and analyzing hundreds of thousands of hours of operation under real-life conditions, Effenco first developed a hybrid electric technology that uses supercapacitors to electrify on-board equipment and partially assist propulsion. These supercapacitors are lightweight, offer virtually unlimited charge-discharge cycles and can operate in both cold and hot climates. This is the same technology that forms the basis of the company’s 100% electric propulsion system.

BANKING ON AN ALL-ELECTRIC SOLUTION – Effenco’s all-electric architecture for vocational trucks outmatches current options in terms of costs. By leveraging the power of ultracapacitor technology, induction charging and unparalleled patented AI algorithms, the company offers a revolutionary all-electric powertrain for heavy-duty vocational trucks for the same up-front price as the diesel equivalent. At the same token, this solution delivers unlimited range and requires 20 times less on-board battery storage than current alternatives. “As counterintuitive as it may sound, the best way to successfully electrify heavy-duty vocational trucks is to reduce the quantity of energy on board,” said David Arsenault, president and cofounder of Effenco.

POWER WHERE AND WHEN IT’S NEEDED – Most heavy-duty vocational vehicles, including bucket trucks, waste collection trucks as well as well as terminal and yard tractors, have regular routes that can be accurately predicted using AI-driven algorithms. Taking its energy efficient design strategy to the next level, Effenco used the data collected in real-time during fleet operations to develop an all-electric solution. Using artificial intelligence algorithms, required energy storage capacity can be optimized and the ideal placement of charging stations can be predicted with spot-on accuracy along the truck’s route. This strategy allows for complete electrification requiring a minimal amount of energy on board. All that is required is enough energy to get from one wireless charging station to the next, which is the key to reducing the cost of purchasing an electric vehicle. This can result in GHG reductions of 30 to 100% depending on the number of charging stations in place.

SUSTAINABLE DEVELOPMENT – Effenco is now active in a dozen countries and has more that 80 highly skilled employees busy deploying its cutting-edge technology worldwide. The company’s all-new all-electric powertrain is a testament to the sheer scope of the company’s projects and its willingness to take on the toughest challenges, including the reduction of greenhouse gas emissions. Its data-centric, flagship solution is a powerful, efficient and affordable tool on the road to achieving sustainable development.

Principal Image : Truck equipped with Effenco’s full electric powertrain

This partner content was produced for Impulsion MTL 2020 – The International Fleet Management Forum.

Continue reading on this subject

Critical and strategic minerals (CSM) traceability pilot project for the Quebec battery sector

PILOT PROJECT FOR QUEBEC’S BATTERY INDUSTRY A number of measures, regulations and laws are currently being put in place in certain countries to secure the local supply chain, or that of allied countries, in Critical and Strategic Minerals (CSM). Europe, for example, has announced the introduction of a Battery Passport from 2027, to track the […]

Read more

LITHIUM-ION BATTERIES : Local and international impact is on the horizon !

The lithium-ion battery sector is a key player in the future of electric and smart transportation in Quebec. Increasing announcements are highlighting the economic and environmental implications both locally and internationally.

Read more

Will industrial strategies chart a new course for the future of Quebec industries?

The Quebec economy—and more broadly the world economy—faces multiple challenges: the climate crisis, supply chain problems, labour shortages, inflation, etc. Quebec has an abundant supply of resources, know-how, and expertise; however, the next points on its agenda should include structuring, developing, and planning industrial activities.

Read more

Hosting a Charging Station?

The new Clean Fuel Regulations, SOR/2022-140, (the “Regulations”) aim to displace the use of fossil fuels and promote the use of electric and hydrogen fuel cell vehicles.

Read more

Ambition EST 2030 : a roadmap for propelling Quebec to the forefront of the electric and smart transportation industry by 2030

Propulsion Québec, the cluster for electric and smart transportation, is announcing Ambition EST 2030, a roadmap for the electric and smart transportation (EST) industry developed in partnership with Deloitte.

Read more

Québec on its way to homegrown battery industry

Québec is well positioned to lead the way in lithium battery manufacturing and ramp up the transition to electric transportation.

Read more

Propulsion Québec releases a new study on extended producer responsibility for end-of-life electric vehicle battery management

Propulsion Québec smart and electric vehicle cluster today released a brand new study entitled Extended Producer Responsibility for Electric Vehicle Lithium-Ion Batteries in Quebec.

Read more

Issues and best practices related to collecting and recycling end-of-life lithium-ion batteries

Propulsion Québec launches a study on the issues and best practices related to collecting and recycling end-of-life lithium-ion batteries in the transportation sector.

Read more

Lithium-Ion Battery Industry: Propulsion Québec Releases Study Confirming Huge Potential for Quebec

Propulsion Québec has released a study revealing the enormous potential of the lithium-ion battery industry in Quebec. The study, carried out by KPMG, looks at global markets for lithium-ion batteries and end-of-life battery recycling, and offers recommendations on how to grow those strategic sectors in Quebec.

Read more